EVs within the air might seem to be an apparent growth, however the know-how to energy them presents a complete new set of challenges. Will eVTOL R&D diverge from, and even reshape, the EV battery business as a complete?

Worldwide business deployment of electrical vertical take-off and touchdown (eVTOL) plane is quickly approaching, and these clear, quiet cloud-runners will maybe quickly be a part of on a regular basis life. Air-taxis and different flight-ready craft stand on the shoulders of the standard EV business, but with out latest leaps in cell vitality density, would by no means have gotten off the bottom. However regardless of a standard future so, eVTOL and EV are vastly completely different.

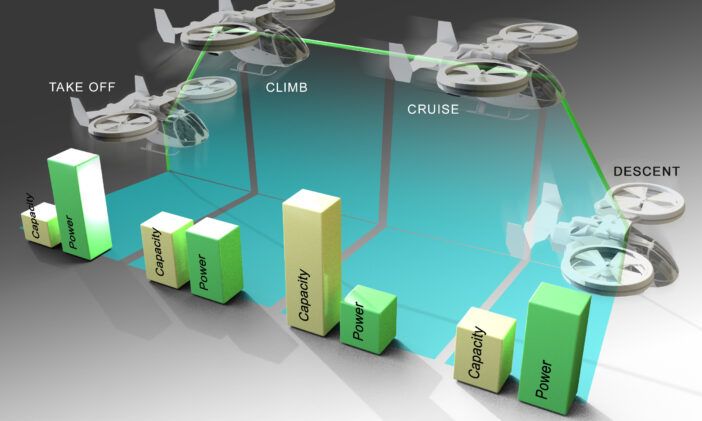

The primary main distinction between these two airborne functions is within the energy necessities.

“They’re large in comparison with an car EV, and over a really brief time span,” says Dr. Ilias Belharouak, Head of the Electrification division at Oak Ridge Nationwide Laboratory (ORNL), the world’s largest vitality lab. “Usually, 30 to 45 seconds of large vitality is required to take [an eVTOL] to a sure altitude, after which cruising that platform for a sure variety of miles, then descending.”

Battery energy is expressed in C-rate, the place 1C is a fee of discharge that will drain it in a single hour. For descent and touchdown, an eVTOL should obtain a whopping 15C for brief durations. Think about margins of error, needing to make a number of touchdown makes an attempt, for instance, and you’re looking at a complete lot of battery.

“We’re speaking about 2-3 order of magnitude in energy in comparison with EVs,” says Belharouak.

ORNL is devoted to unravelling the secrets and techniques of high-power batteries, working experimental designs by a rigorous testing course of that simulates the extraordinary calls for of take-off, cruise and touchdown.

“In our laboratory we’re making an attempt to imitate the situations beneath which the flying platform would function,” says Belharouak. “So, it’s about mechanical stress, vibration and altitude and the low temperature that entails, situations not seen for ground-EVs.”

Typically, researchers are discovering that it comes all the way down to the particular composition of the electrolytes throughout the cell and are creating formulations that may stabilize the chemistry inside these cells beneath such situations.

Sure battery and cell options are obligatory for high-power output, and ORNL is investigating that too. “You could have vital design selections,” says Belharouk, “Efficient energy output depends upon the thickness of the electrodes, in addition to the electrolytes used within the cell. In our R&D one of many key improvements is within the optimisation of the ionic conductivity and the transference variety of the electrolytes.”

However what they’re discovering is that there are trade-offs. Choices should be made on balancing the wants of eVTOL, whereas additionally contemplating vary and security.

“There’s undoubtedly a compromise,” says Belharouk. “Automotive EV batteries are vitality dense, and due to that we are able to run them for a whole lot of miles. However these sorts of batteries should not designed to supply excessive energy over a shorter interval.”

Security within the air

Security within the air

The primary attraction of eVTOLs is that they’re runway impartial, they will land and takeoff from a comparatively small footprint. As soon as within the sky, many function like a traditional plane, with aero foil wings and ahead thrust propellors.

“For each kilogram of battery weight that we now have to hold, that’s one other 10 newtons of vertical thrust that we have to get the factor up into the air,” says Ian Thomas, founding father of Novel Engineering, working immediately on new approaches to eVTOL security. “So, you don’t wish to find yourself with diminishing returns. That battery wants to have the ability to pack the additional energy.

“Conventional aviation makes use of jet gas, as a result of it’s received excessive particular vitality. 12,000 wh/kg. So these are nice numbers, whereas lithium-ion batteries are about 300 wh/kg. So, if you wish to fly from London to Barcelona you’d want 5 tons of jet gas, however [for an eVTOL] you’d want 200 tons of battery.”

These are ballpark figures, however the image is obvious: to in the future supplant the Boeing 747, each vitality density and particular vitality might want to ramp up. However at the moment, eVTOL’s and their batteries are restricted to a lot shorter flights, and far lighter plane.

Anyone who has been watching the event of eVTOL might be conscious that security certification is a serious hurdle, and one which has pushed again the commercialization course of. “The plane should be rather more ruggedized and sturdy to the actually excessive forces concerned in a crash,” says Thomas.

For one of the best of causes, FAA (USA) and EASA (EU) approval require stringent proof that an eVTOL is protected. Just lately, this has concerned Archer Aviation subjecting its five-seater eVTOL Midnight’s batteries to 50ft drop impacts. As a result of approval might be such an arduous and time-consuming course of, Novel Engineering has developed an software they name Secure Cert AI, which helps expedite the info crunching concerned. They are saying it may possibly pace up the method by 80%.

“It was impressed by the protection circumstances we do for a lot of of our purchasers,” says Thomas. “Might we do it quicker? Extra effectively? Extra cheaply? Combining that with the most recent developments in AI and LLMs, it’s an automatic instrument that may do plenty of the legwork in security.”

And additional instruments for security are direly wanted. Even momentary and partial failure in energy provide can result in disaster whereas airborne, and energy calls for create additional issues.

“Once you draw excessive energy to the batteries, the baseline electrolytes will warmth tremendously,” says Belharouk, “Which might result in some security considerations.”

These embody thermal runaway, an oddly reassuring phrase that right here describes an eVTOL turning right into a blazing fireball and crashing to earth, which is a big concern for each passengers and whoever may be strolling about beneath.

Once more, tweaking the electrolyte formulation is the strategy ORNL has gone for. Nevertheless, many eVTOL poised for manufacturing as a substitute have devoted liquid-cooling techniques, notably the Lilium Jet and the Joby S4. This comes at a weight value, as much as 40kg, in addition to system energy wants.

Floor to air

Floor to air

To date, all this speak of electrolyte and cell design has skirted round a easy and really fascinating truth. The eVTOL producers, be it Archer, Beta, Lilium and Joby within the US, or EHang in China, are all making use of current cells. True, there are confirmations that the battery packs are being assembled in-house. The necessity for fast testing cycles, increased energy calls for, housing that matches the aerodynamic design all imply it’s a necessity that cells be customized assembled into the packs.

Archer’s Midnight makes use of E-One Moli Vitality Firm’s Molicel P42A cylindrical lithium-ion, recognized for high-discharge capability. And Joby’s S4 makes use of 811 NMC cathode, graphite anode, broadly utilized by Tesla.

Given what ORNL says concerning the huge variations between the wants of cells in air as in comparison with floor, why are OEMs invariably utilizing the usual cells present in commercially obtainable EVs? To commercialize rapidly, OEMs don’t wish to take dangers on ‘straight out of the lab’ cells, preferring these tried and examined in mass manufacturing. Novel cells pose a double threat, on the one hand that the eVTOLs will fail unexpectedly after commercialization, on the opposite that manufacturing must be halted and remembers issued.

Proper now, OEMs are dashing to certify and commercialise, with traders ploughing enormous sums into firms but to show a revenue. This primary crop guarantees to be purposeful, albeit with restricted vary. With out cells particularly designed for air journey, the price of this relative predictability might be inefficiency, as parts designed to push a car alongside the bottom wrestle with their new perform.

“The eVTOL program presents a novel alternative for making a brand-new kind of battery with very completely different necessities and capabilities than what we now have seen earlier than,” says Belharouk. “It should be designed for the particular software. So, in manufacturing, we can not design them as ground-EV batteries.”

All that is going to have wider implications for the EV sector, probably pushing new chemistries just like the air-battery and strong state, probably making higher-power obtainable to the ground-EV as nicely. Finally, somebody goes to be designing and assembling these cells. CATL have signalled early curiosity and have already shaped a partnership with eVTOL start-up Autoflight. OEMs are pushing forward, and for the second they don’t seem to be able to act on the recommendation of nationwide analysis establishments like ORNL. For the instant future, the goal is simply to get a product that’s purposeful, protected and compliant with rules. Nevertheless, as quickly as that race is run, one other one begins; to develop and deploy specialised cells, tailored for the skies.

Joby Aviation S4

With its outer casing comprised of layers of light-weight carbon fibre, propulsion comes from six electrical motors, two on the V-tail, 4 on the wings. It’s a tiltrotor, that means the propellors swivel 90 levels after take-off to fly like an odd airplane with a 39ft wingspan. It weighs in at beneath 2000kg and has a most payload of 453kg.

For redundancy and security every propeller has energy from two separate motors, every of which is linked to the 4 on-board batteries. If an inverter or battery fails, the propellor continues to perform. Toyota has invested $400 million into Joby, in addition to offering expertise immediately. At the moment a production-prototype, there’s hypothesis that they may supply cells for full scale manufacturing from the TBMNC $2.5bn plant, presently beneath building.

With vertically built-in manufacturing, Joby assembles its battery packs from NMC cathode, graphite anode cells in-house. This enables for quicker testing and growth, though the 811 is understood to be a little bit extra thermally unstable and in want of extra cooling. Joby has attracted Tesla’s massive hitter engineer John Wagner as Powertrain Lead, they goal to start out components manufacturing and commercialization in early 2025.

Overair Butterfly

Thought-about a 2nd wave OEM, Overair payments the Butterfly as a sustainable, quiet, rideshare. It boasts being one of the city-friendly eVTOLs at 55db and constructed with a view in the direction of scaling as much as bigger plane. It may take a payload of 4 passengers, pilot and baggage, with airport transfers and ambulance service in thoughts.

The 6m extensive propellors are bigger than most eVTOLs. It adjusts Optimum Velocity Tilt Rotor (OSTR) for RPM and Particular person Blade Management (IBC) for angle, all within the title of effectivity good points and a easy flight. Korean Hanwha Programs and Hanwha Aerospace invested $115 million and are co-developing the battery packs. Additional particulars are sparse, however John Criezis, Head of Mobility, has talked about that the Butterfly runs on typical cells obtainable at scale.

With a variety of 100 miles and a 200mph high pace, it’s also designed to resist inclement climate, warmth and better altitudes. Toray Composite Supplies America provides the T1100 carbon fiber and 3960 epoxy prepreg which make up the airframe and rotor blades.