With direct ties to over 170 world championship titles throughout two- and four-wheeled motorsports, Akrapovič may be probably the most profitable go-fast store in historical past. But, for a lot of fans, their first publicity to the model seemingly didn’t come from the racetrack—it got here from the aftermarket. Their light-weight, fantastically welded titanium exhaust techniques have develop into legends in garages and boards across the globe.

A Legacy Solid in Racing

The corporate was born out of ardour—and necessity. Igor Akrapovič, a former motorbike racer and tuner, started modifying bikes for himself and his fellow racers within the early ’90s. At a time when solely Japanese and American firms have been producing high-end exhausts, Igor noticed a chance to fill a efficiency hole in Europe. The massive breakthrough got here in Germany’s Superbike World Championship, the place a privateer named Jochen Schmidt surprised the paddock with back-to-back podiums utilizing an Akrapovič system. One of many few variations between his Kawasaki and the manufacturing unit bikes? The exhaust. From that second, the cellphone didn’t cease ringing—beginning with Kawasaki Japan.

By 1999, Akrapovič was supporting all Japanese manufacturing unit Superbike groups. In 2002, they entered MotoGP, and immediately provide exhaust techniques to over 80% of the premier class. On the four-wheeled facet, they’ve contributed to greater than 40% of WEC automobiles, together with a number of Le Mans-winning machines. Their first main victory in automotive endurance got here with Porsche on the Nürburgring 24h in 2008.

On this uncommon behind-the-scenes look inside Akrapovič’s sprawling amenities close to Ljubljana, Slovenia, we comply with the trail from uncooked titanium to world-beating {hardware}, uncovering the meticulous engineering and racing DNA that fuels all of it.

Day One: R&D and Lab Testing

Our first cease was the fabric testing lab, the place uncooked supplies and pattern castings are pushed to their limits. Each 100 elements or so, Akrapovič grabs a pattern to examine for hardness, weld integrity, and chemical composition. If one thing’s off, manufacturing halts. It’s a high-stakes sport the place metallurgy meets motorsport.

Subsequent, we moved to the measurement middle, the place every little thing from jigs to completed elements is scanned and verified. Their “scan field” permits them to quickly prototype or reverse-engineer low-volume functions, excellent for customized jobs or new OEM collaborations. The model’s famed casting division—full with its personal foundry—lets them create extraordinarily complicated shapes, like turbo impellers and collector housings, which might be close to unattainable utilizing conventional manufacturing strategies.

Dyno Time and Sound Science

No efficiency exhaust model can be full with out an in-house dynamometer, and Akrapovič’s is as superior as you’d anticipate. They use it to validate energy positive aspects, optimize sound, and guarantee emissions compliance, benchmarking each design towards OEM techniques. However energy isn’t the one precedence—sound is sacred. Akrapovič’s crew of engineers conduct sound engineering exams to dial in acoustic character and adjust to race laws. In some ways, they deal with sound the way in which a composer treats tone. The end result? Exhaust notes which are distinct, aggressive, and immediately recognizable.

The Race Division

In a separate constructing solely is Akrapovič’s race division, staffed by 18 specialists. Their focus? Growing cutting-edge techniques for MotoGP, WorldSBK, and endurance racing. They’re additionally embedded trackside when wanted, gathering real-time suggestions and aiding manufacturing unit groups. Greater than 90% of their knowledge comes from OEM companions, with meeting happening in the primary manufacturing line.

Apparently, some race exhausts are designed to final simply 2,500 km, relying on the race format. That’s underneath 1,600 miles—simply sufficient for one intense weekend earlier than being retired.

The Sturdiness Lab: Meet Sabrina

Sturdiness issues, particularly for road-going functions and long-distance racing. Enter the Motorbike Sturdiness Dyno (MDD), the place bikes are examined underneath excessive circumstances utilizing a robotic system affectionately nicknamed “Sabrina.” These exams usually exceed 10,000 kilometers of simulated abuse—equal to over 100,000 kilometers on the highway. A fueling system is hard-plumbed into the bike to maintain exams operating repeatedly. As soon as the run is full, engineers disassemble the exhaust for evaluation, guaranteeing it handed not simply the efficiency check, however the punishment check.

Past Exhausts: The Full Portfolio

Akrapovič could also be identified for exhausts, however additionally they produce carbon fiber aero elements, diffusers, mirror caps, and extra. Whereas the carbon elements are extra about visible enhancement than efficiency, they uphold the corporate’s light-weight design philosophy. Their bike product line covers every little thing from scooters and avenue bikes to off-road and journey fashions. On the automobile facet, they provide full techniques—from cat-back setups to downpipes, and even GT3-grade parts for elite motorsport purchasers.

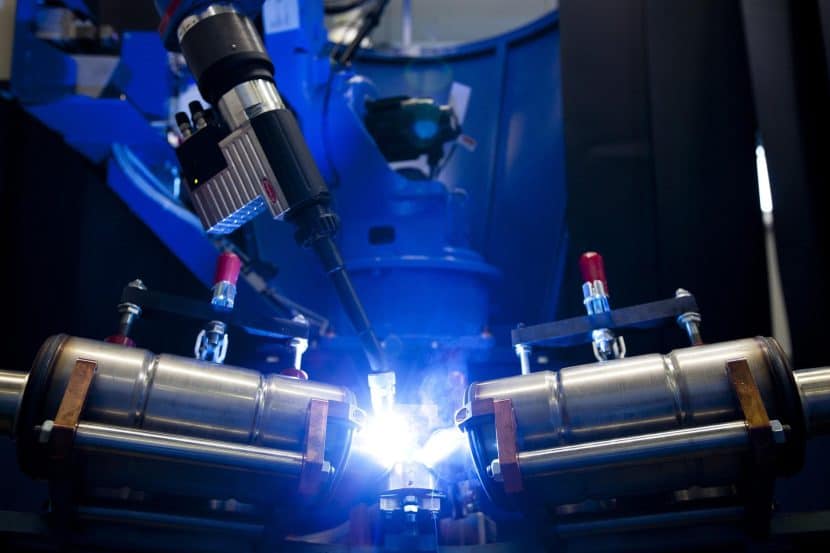

Day Two: Serial Manufacturing

The second day of our go to introduced us to the serial manufacturing facility, an enormous constructing roughly thrice the dimensions of Akrapovič’s HQ. Inside, we discovered the “tube maker” (precisely what it seems like), slicing stations, and each handbook and robotic welding bays. Due to the intricacy of titanium and composite parts, the corporate blends human craftsmanship with automation. Ultimate meeting and high quality management are nonetheless carried out by extremely educated workers—a lot of whom come from technical backgrounds or motorsports themselves.

Every part stays 100% made in Slovenia, unfold throughout 4 amenities clustered round a hill simply exterior Ljubljana. Even the corporate’s emblem just lately acquired a refresh by means of R&D. Regardless of its dimension and success, Akrapovič stays a hands-on firm fueled by racing ardour and technical obsession.

From Storage to Grid

What started as one racer’s mission to go sooner has develop into a globally revered identify, trusted by the likes of Bentley, Lamborghini, Porsche, and Yamaha. With over 2,000 aftermarket companions, dozens of manufacturing unit race applications, and a fame for obsessive materials science, Akrapovič is far more than an exhaust model—they’re a benchmark in efficiency engineering.

Touring the manufacturing unit revealed what photographs and YouTube clips by no means may: this isn’t only a model. It’s a craft. One which was born in racing—and formed by it.