Sponsored by Schuler.

After buying the Italian Sovema Group, Schuler is regularly establishing itself as a system provider within the discipline of battery manufacturing. The primary profitable large-scale initiatives present that the technique is working.

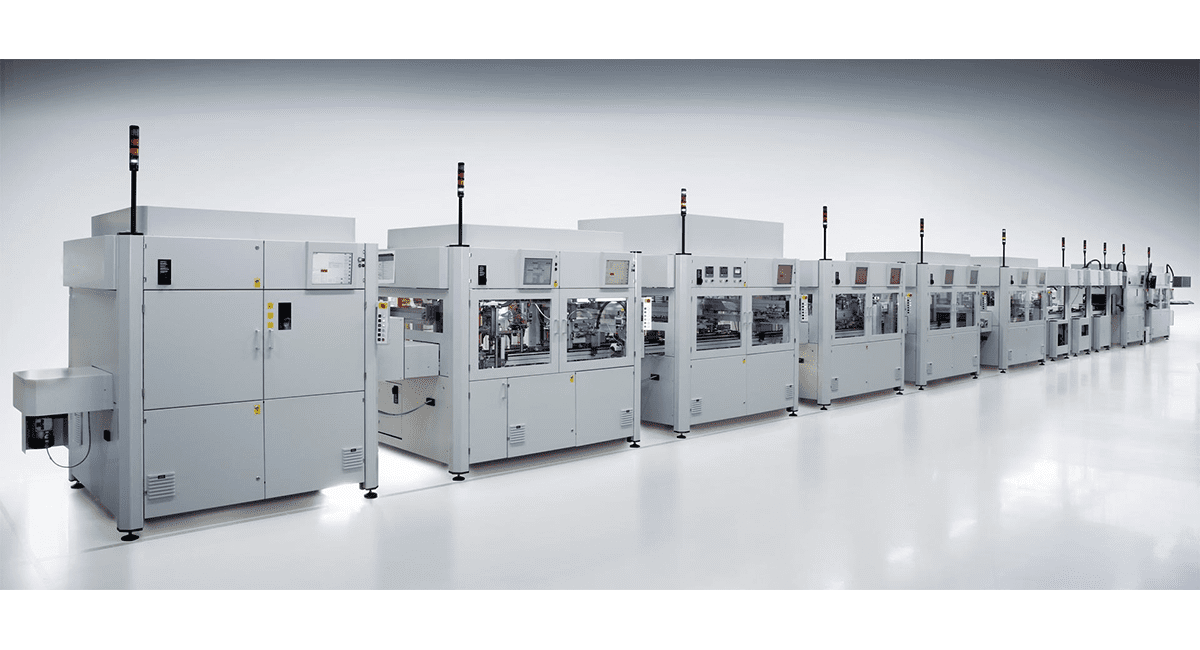

Schuler handed an essential milestone as a provider for gigafactories with the development of a formation line for a big German battery cell producer. After the deliberate begin of manufacturing in Might 2025, the road will have the ability to produce round 80 cylindrical lithium-ion cells per minute. Along with planning, manufacturing, and assembling the road, Schuler has additionally taken on all the intralogistics, the metal development, and the implementation of digital options that embrace a track-and-trace performance for the plant.

The growing enterprise exercise, that Schuler has solely just lately developed for the manufacturing areas of cell meeting and formation, follows a clearly outlined technique. The ANDRITZ Group, because the mum or dad firm of Schuler, has elevated battery manufacturing for the electromobility sector with a complete of seven progress initiatives. The purpose: assist battery makers produce aggressive batteries in Europe and America.

Step one was the acquisition of the Italian Sovema Group in August 2022. Within the automotive sector, Sovema made a reputation for itself over the previous ten years as a system provider for pilot and laboratory initiatives within the discipline of lithium-ion batteries. As well as, the corporate is taken into account a number one international supplier of turnkey programs for the mass manufacturing of lead-acid batteries. The US subsidiary Bitrode additionally contributes extra tools and know-how within the discipline {of electrical} battery testing of cells, modules, and packs.

With Sovema’s experience and expertise, Schuler is ready to cowl all the manufacturing line within the cell meeting and cell ending areas: the notching and stacking processes, manufacturing of housing elements, and filling of electrolytes from formation to ageing to closing sealing.

Schuler can increase the meeting and formation manufacturing traces and scale them up for the mass manufacturing of battery cells. Earlier than the takeover, Sovema primarily manufactured laboratory and pilot programs.

When it comes to course of know-how, Schuler can draw by itself experience within the manufacturing of prismatic and cylindrical battery cell housings (“Can & Lid Manufacturing”), for which it has been constructing vegetation since 2015. Within the discipline of cylindrical cell housings, the Göppingen-based firm just lately delivered 4 absolutely automated turnkey manufacturing traces for a world-renowned carmaker in Germany and the USA. One other line for the manufacturing of prismatic housings, with a manufacturing pace of 100 housings per minute, went to Hungary.

Experience and capacities from different enterprise areas of the ANDRITZ Group can be found. For instance, the group has been manufacturing centrifuges for lithium mining for the reason that Sixties and in addition provides filter and drying programs which are wanted in powder processing for the manufacturing of lively cathode materials. ANDRITZ additionally has in depth know-how in calendering processes, the place rolls are used. Final, however not least, ANDRITZ’s personal recycling division contributes in depth information and expertise within the areas of dismantling, deep discharge, and recycling of batteries. The main target right here is on developments over the subsequent 5 to 10 years, when growing gross sales figures will imply that an increasing number of manufacturing waste from used electrical autos must be recycled.

In November 2022, Schuler obtained an order from the Fraunhofer Analysis Establishment for Battery Cell Manufacturing FFB at its Münster web site to design a cell meeting line for large-format pouch cells in three totally different lengths. One other main undertaking is at present underway for considered one of Germany’s main automotive producers. The main target of this undertaking is the development of a pilot cell meeting line for the manufacturing of revolutionary “solid-state” battery cells. In comparison with standard lithium-ion batteries, these solid-state cells have various market-relevant benefits. These benefits relate to essential security facets (in contrast to lithium-ion batteries, solid-state batteries can not catch hearth); they’ve greater vitality density than lithium-ion batteries and might generate a considerably larger vary for electrical autos. Shorter charging occasions are one other important benefit in the case of assembly essentially the most demanding necessities within the discipline of electromobility. The turnkey handover of the plant for this main undertaking is scheduled for Might 2025.

Dr. Hermann Uchtmann, Head of Schuler’s “Battery Giga Initiatives” enterprise unit, notes the explanations behind present market restraints for plant producers within the discipline of battery manufacturing: “Taking the present gross sales figures for electrical vehicles as a place to begin, the battery marketplace for automotive functions is in a part the place the exaggerated expectations have arrived within the ‘trough of disillusionment.’ We count on demand to select up considerably once more within the coming years. We’re utilizing the time successfully to optimize our merchandise for gigafactory traces within the space of battery cell manufacturing for market demand.”

However to what extent can Schuler seize the market share from rivals within the Far East? For these in cost, essentially the most highly effective arguments listed below are straight linked to the core ideas of innovation, high quality, and effectivity. Uchtmann states: “Sooner or later, we need to make larger use of our revolutionary edge within the discipline of plant know-how, significantly within the space of large-scale manufacturing. That is related for a goal group, such because the automotive sector, which locations the very best calls for on manufacturing. That is how we are able to mix our excellent high quality options and the particular cost-effectiveness of our programs into a standard denominator.”

In battery cell manufacturing, the excessive manufacturing high quality is mirrored, above all, in low rejection charges. One other essential issue, particularly for the German market, is the bottom potential vitality consumption that’s measured towards the consumption values of rivals. Uchtmann says: “Right here, for instance, we are able to obtain excessive vitality effectivity values of just about 90 % utilizing the formation electronics we make use of.” In line with Uchtmann, additional financial savings might be made by minimizing the area required, particularly the place excessive prices can come up for the operator—akin to working drying rooms.

For Uchtmann, the providers that accompany the plant development clearly converse “professional Schuler.” “A decisive benefit is that our vegetation are predestined to be used within the European market. Not like in Asia, European battery cell producers are accustomed to having their vegetation delivered, assembled on-site, and arrange prepared for operation. Added to this are the dependable upkeep and restore providers that we offer within the after-sales sector, together with extremely dependable spare elements deliveries. It’s right here, within the continued productiveness and availability of the plant, that our experience actually pays off: the client then has a associate at their facet that they’ll depend on!”